Client: EXEON

Year: 2022

Developed as part of the internal project focusing on EDS service - design process optimization. Initially developed as a demonstrator showcasing possibilities of the EDS tool. Latter underwent an advanced engineering development focusing on intelligent tilting system.

Driving a mini mobility vehicles can be challenging for inexperienced users. Advanced tilting systems have potential to provide several advantages by increasing safety through superior stability in various conditions as well as improved driving experience.

Our perspective

We’ve engineered a groundbreaking solution in the realm of vehicle dynamics

with the development of our 4-wheeler tilting suspension system. This innovative system, controlled by precision actuators, allows for a dynamic adjustment of the vehicle's tilt during turns, significantly increasing safety by reducing the risk of rollover in critical maneuvers. Furthermore, this adaptive tilting mechanism enhances the driving experience by providing a more engaging and responsive handling characteristic, thus elevating the vehicle's performance capabilities.

[1.0] Concept Ideation

Info

The initial vehicle architecture concept was generated using the EDS TOOL (more about it in its dedicated section). Based on the initial geometry, the first sketches of the designed vehicle were created. The 2-person urban vehicle was to feature a contemporary dynamic silhouette and specific details in the form of lights and a front windshield connected with the roof.

[2.0] Concept Development

Info

Subsequent sketch iterations led to a more refined form of the vehicle. Each sketch iteration tested different aspects of the design, exploring the impact of minor changes in proportions and details on the overall perception of the vehicle.

[3.0] Conceptual Engineering

At this stage, basic mechanical modules were included, such as suspension elements, drive, battery power, and the vehicle frame.

Info

Simultaneously with the search for silhouette and appearance, we undertook work on detailing the technical assumptions and developing the basic vehicle architecture.

[3.1] Vehicle Architecture

Info

In the next stage of work, we developed individual systems that make up the vehicle's architecture to a more detailed level. Considering the interdependencies of individual components and their impact on the whole provided concrete conclusions for further developmental work.

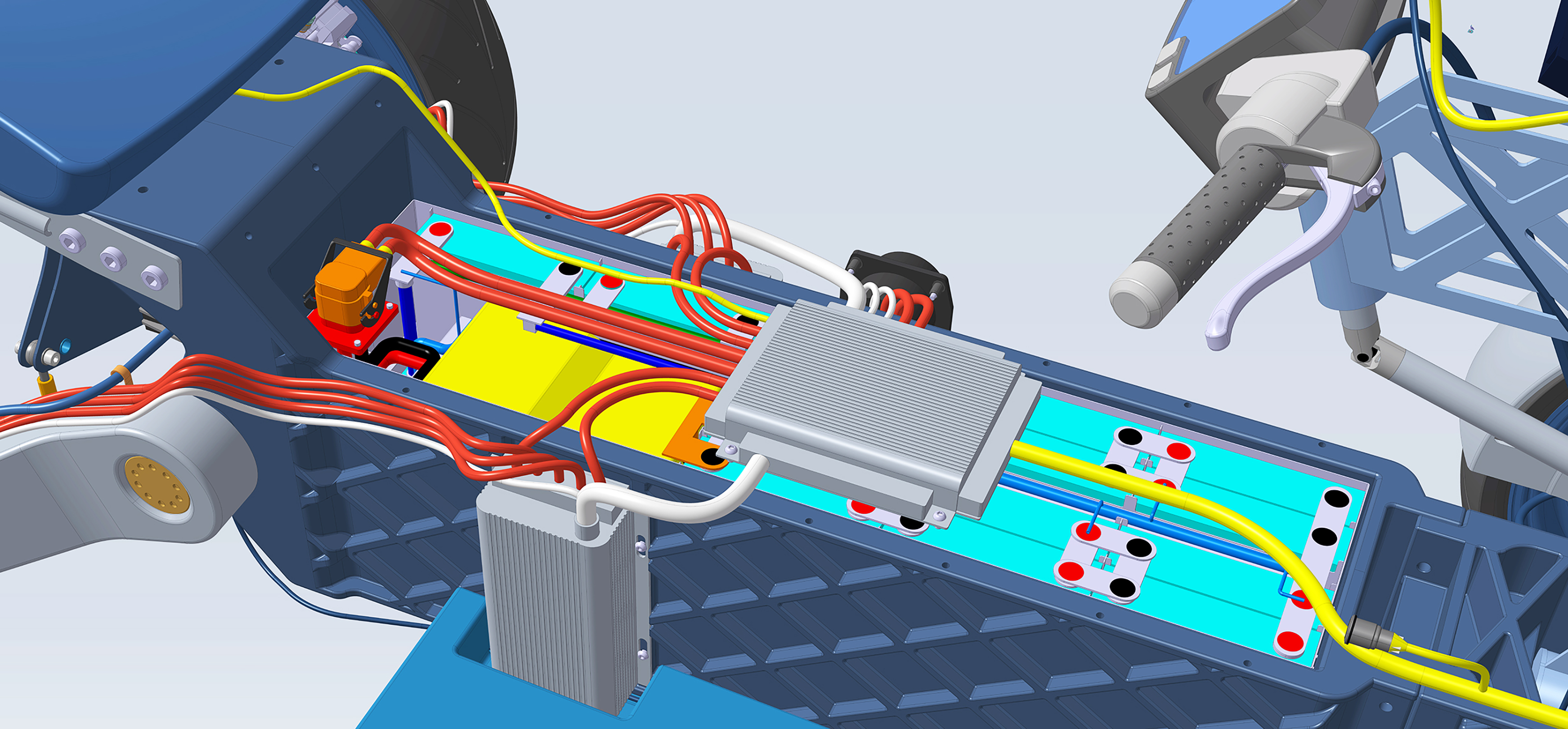

[3.2] Electrical Engineering

Info

An essential element of vehicle development was its power system. In the next design steps, we developed a complex power system including a battery sarcophagus, battery management system, as well as the layout of cables necessary for powering and integrating the entire system.

[4.0] Development Iterations

Info

Comprehensive vehicle design assumes the necessity of continuous verification of solutions at subsystem levels, their interdependencies, and their impact on the overall solution. The iterative approach was key to catching any discrepancies and making appropriate corrections.

[5.0] Vehicle Platform

Info

The most important and ambitious aspect of the project was the development of an active suspension system. The planned 4-wheel vehicle was to provide unique driving capabilities, with a high level of safety and comfort. From the beginning, planned as a type of universal platform for equal applications, the suspension system was to allow for the use of different types of superstructures.

SUSPENSION

[6.0] Active Suspension Development

Info

Within the suspension system, one of the biggest challenges was developing active suspension assistance, giving the ability to control driving dynamics and suspension work to improve balance and driving properties. The element responsible for this aspect is integrated electric assistance and a series of sensors providing data to the unit managing active assistance.

[6.1] Suspension Detail Development

Info

In subsequent stages of project development, individual suspension system elements gained more detailed form - so that finally, a series of simulations and tests could be conducted for the developed solutions.

[6.2] Suspension Tilting Development

Info

Particular attention was paid to aspects related to the tilting system present both at the front and the rear of the vehicle. Synchronizing their mutual work was a significant challenge from the point of view of work efficiency and meeting other design assumptions.

[7.0] Vehicle Integration

Info

The final stage was combining all modules into one coherent whole. As illustrated by the image above, the individual layers of the project overlap, starting from the sketch, preliminary technical solutions, visualizations, detailed module development, to the outer shell - creating one harmonious whole.

[8.0] EDS verification

Info

One of the significant verification elements in this experimental project was comparing the initial assumptions created using a tool developed by EXEON for quickly generating the initial vehicle architecture based on input data.

[11] Visualizations

Info

At the end of this project phase, we prepared a series of visualizations showing the vehicle in action, by emphasizing the dynamics of the silhouette and the symbolic expression of unique driving impressions.

DESIGN & ENGINEERING TEAM