OUR SERVICES

At EXEON, we combine specialized knowledge and practical insight to develop…

advanced mobility solutions. Our range of services includes engineering, industrial design, CAx, and consulting in transportation development. We aim to offer our clients a cohesive journey from the initial idea to the final market introduction, supporting them at every development phase.

[OUR EDGE]

Led by experienced professionals, we leverage deep expertise in engineering, design, and project management to craft innovative mobility solutions. Our approach combines strategic insight with creative ideas, addressing complex challenges across diverse transportation modes.

Strategic Foresight

Out of the Box Ideas

Multidisciplinary Approach

Open for Challenges

Proven Track Record

Agile & Adaptable

Problem Solving

Advising & Consulting

1/3

[ENGINEERING]

We excel in managing complex, multidisciplinary technical projects, applying system engineering principles throughout the entire project life cycle. Integrating advanced methodologies and state of the art design tools, we ensure that both leadership and support roles enhance project outcomes with efficiency and innovation.

Systems Engineering

Turnkey Projects

Manufacturing Ready

Advanced Engineering

Electrical & Software

DFMEA, DFA, DFM

2/3

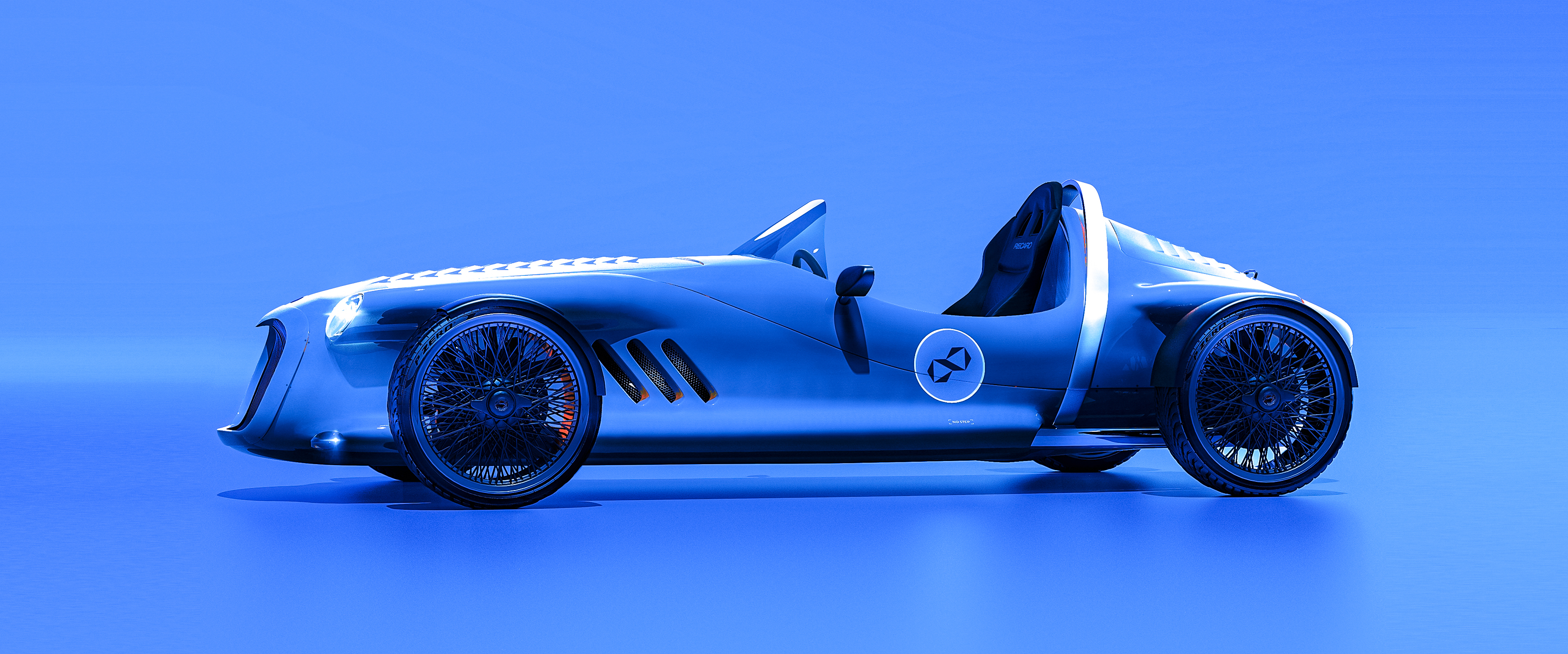

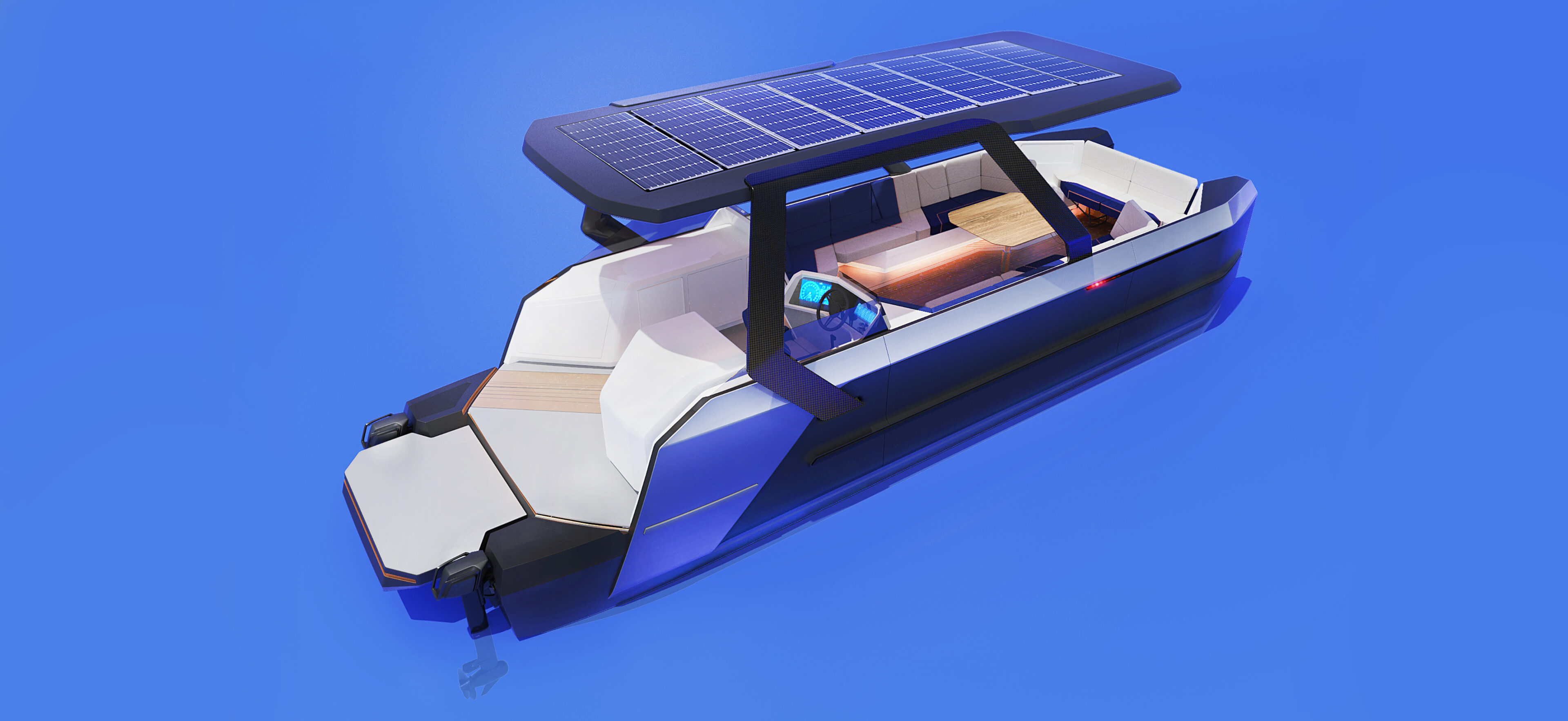

[INDUSTRIAL DESIGN]

We specialize in mobility design and future transportation research, providing complete services from concept development to detailed design execution. Our expertise spans user experience, functionality and aesthetics, guaranteeing a holistic approach to every project. We develop complex solutions across various means of transportation.

Design Research

Conceptual Design

Prototyping & Testing

Form & Function

Design Strategy

UX, UI, VR, MR

3/3

ENGINEERING & DESIGN CAPABILITIES

EXEON uniquely combines engineering and design, offering a cohesive service that drives innovative mobility solutions.

We begin with a deep understanding of the user and the wider usage context, which forms the basis for our research, conceptual design, and engineering efforts.

We are capable to work on complex, multidisciplinary technical projects based on system engineering principles.

We do not stop at the development of a product; our process extends to post-development support, testing, and market implementation, ensuring the successful launch and acceptance of our solutions. Our integrated, end-to-end process ensures that our designs are not just innovative, but viable, sustainable, and truly transformative.

We have the capability to either lead or support through every stage of a project’s lifecycle and scope. This includes forming goals and requirements, conceptual design and engineering, conducting engineering calculations and simulations, and ensuring regulatory compliance. Our expertise extends to technical development, CAD modeling, detailed design, and preparing production documentation (3D / 2D).

Our engineering expertise spans mechanical, electrical, and mechatronics fields, enabling us to tackle complex, multidisciplinary technical projects grounded in systems engineering principles. We adhere to Design for Assembly (DFA) and Design for Manufacturing (DFM) methodologies, including tools like DFMEA, to ensure quality and efficiency.

Our project management approach incorporates Agile methodologies, enhancing flexibility and responsiveness. Additionally, we conduct thorough market research to assess supplier offerings and maintain close collaboration with suppliers and manufacturers to streamline the development process.

Our creative process is anchored in a comprehensive approach to Industrial Design, blending in-house methodologies with strategic foresight and innovation strategy. Our fields of focus span from design research through to detailed design, enriched by a deep understanding of human factors and aesthetics.

We prioritize transportation design, implementing design strategies that ensure every project is future-ready. Our process encompasses experience testing and precise product definition, ensuring that each product anticipates user needs and industry shifts.

Our process is enhanced by advanced CAx tools and methodologies, catering to detailed engineering, concept design, and visual presentations. Our toolkit includes industry-leading software such as Catia V5 & V6, Siemens NX, Creo, Autodesk Inventor, Inventor Nastran, Fusion 360, Blender, and Keyshot.

We are experienced at adopting clients’ standards and methodologies or applying our own established standards to ensure precision, efficiency, and adaptability across all project phases. This flexibility allows us to seamlessly integrate with our clients’ workflows or guide projects with our in-house expertise, ensuring that every design is executed to the highest quality levels.

Our prototyping and testing capabilities are extensive, embracing both cutting-edge technology and traditional methods to bring designs to tangible reality. Our suite includes VR (Virtual Reality) & AR (Augmented Reality) tools, enabling immersive design reviews and client presentations that provide a realistic sense of space and functionality before physical prototypes are created.

We excel in creating detailed mock-ups and employ clay modeling to refine shapes and ergonomics, allowing hands-on interaction with the design. Our capabilities extend to rapid prototyping methods such as 3D printing and vacuum casting as well as electronics prototyping, including PCB layout design and wiring harness design and construction.

By seamlessly integrating these elements, we manage the transition from concept to fully operational prototypes, streamlining the development process to meet precise project goals efficiently.

Our vehicle engineering framework includes:

Mechanical package – strategically arranging components for maximum efficiency.

Vehicle architecture – engineering the foundational structure for optimal performance.

Occupant package – configuring interior space to prioritize safety and ergonomics.

Chassis for EVs – designed to accommodate the unique needs of electric propulsion.

Body & Glazing – focusing on structural integrity and aerodynamic efficiency.

ADAS & Autonomy Sensors – embedding cutting-edge technology for enhanced safety.

Doors, Hatches, & Access Points – engineered for secure and convenient access.

Steering & Suspension – calibrated for precise handling and ride comfort.

Battery Pack – integrated for energy efficiency and optimal weight distribution.

Lighting – engineered for visibility and compliance with safety standards.

HVAC – designed for effective environmental control within the vehicle.

Thermal Management System – maintaining ideal operating conditions for all components.

Interior & Seating – arranged for optimal space utilization and comfort.

Wheels – selected for their performance attributes and compatibility with vehicle dynamics.

COOPERATION MODELS

DESIGN SERVICE EDS